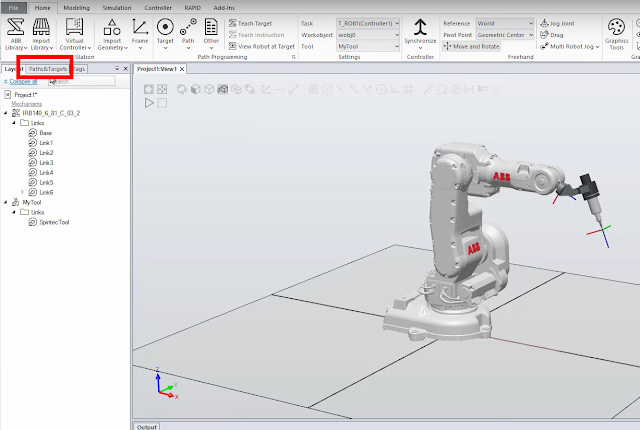

RobotStudio® Tutorial – Getting Started 3/5

Attaching a tool to a robot flange.

Add Target Points

Right Click and Create Path

🛠️ Procedure: Setting a WorkObject on an Imported Disc in RobotStudio

🎯 Goal:

To create and accurately align a WorkObject to a thin disc geometry (100 mm radius) so the robot can perform operations like sanding relative to the disc’s coordinate frame.

✅ Step 1: Import or Locate the Disc Geometry

-

Ensure your disc is properly imported into the 3D world of RobotStudio.

-

Confirm it's visible in the Layout tab and selectable in the 3D view.

✅ Step 2: Create a New WorkObject

-

Go to the Home tab → click WorkObjects → choose New WorkObject.

-

Give it a clear name, e.g.,

DiscWorkObject.

✅ Step 3: Attach or Align the WorkObject to the Disc

Option A: Use “Attach To” (Recommended if disc appears as selectable object)

-

Right-click the WorkObject → Modify Position.

-

In the pop-up, use the “Attach to” dropdown → select your disc from the list.

-

RobotStudio will auto-align the WorkObject origin to the disc’s local frame (usually its center).

Option B: Manually Measure and Enter Coordinates (For precision)

-

Use the Measure Tool:

-

Go to the Modeling or Home tab → click Measure Distance.

-

Measure from the world origin or fixture to the center of the disc.

-

-

Right-click the WorkObject → Modify Position → enter the measured X, Y, Z coordinates manually.

-

If needed, adjust the orientation angles (Rx, Ry, Rz) to ensure the Z-axis points normal to the disc surface.

✅ Step 4: Verify and Fine-Tune Orientation

-

Use the axis visual indicators to confirm:

-

Z-axis = sanding tool approach direction (typically perpendicular to disc surface).

-

X/Y-axes = aligned with the disc plane as needed.

-

-

Use rotation handles or angle input for refinement.

✅ Step 5: (Optional) Attach Disc to WorkObject

-

Drag the disc geometry under the WorkObject in the Layout tree to associate them.

-

This ensures the disc moves with the WorkObject if it's repositioned later.

✅ Step 6: Use the WorkObject in Programming

When defining movement instructions in RAPID, reference the new WorkObject:

MoveL p_SandPoint1, v200, z50, tool0\WObj:=DiscWorkObject;

🔒 Step 7: Lock Position (Optional)

-

Right-click the WorkObject → Lock Position to prevent accidental changes during layout adjustments.